Advanced Desalination Membrane Technology

Active versus Passive membrane separation – therein lies the core difference between our products and conventional membranes used in desalination.

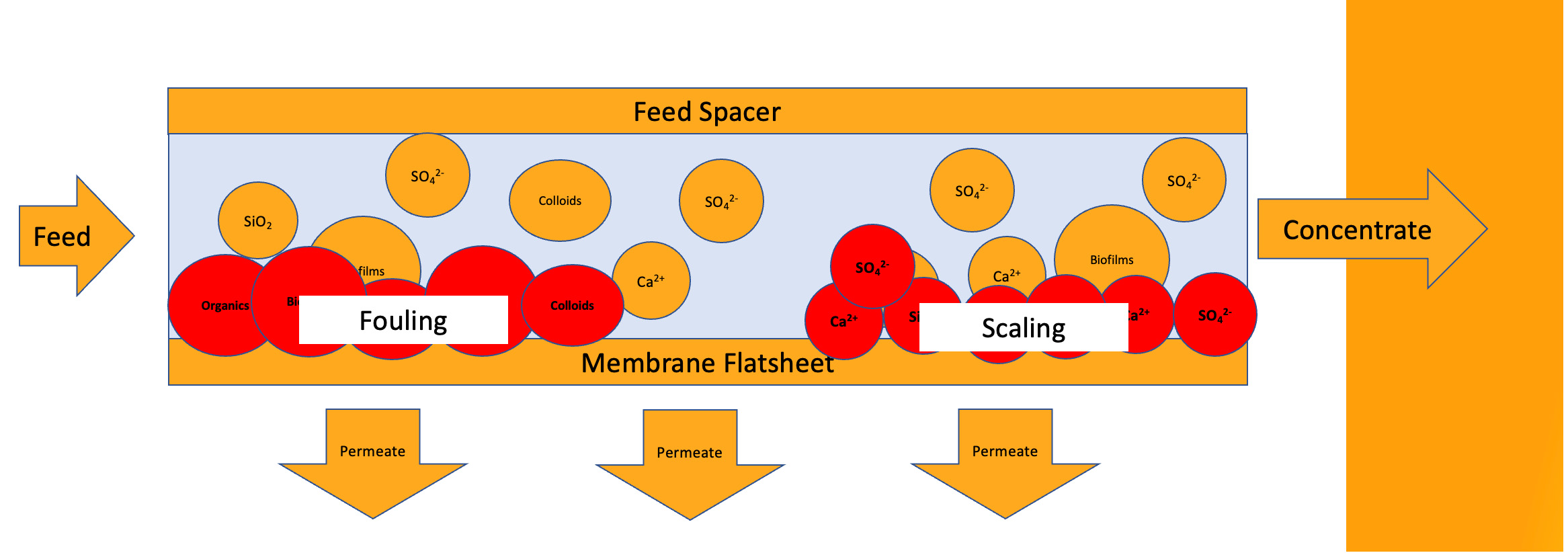

Conventional membranes used in desalination function passively. They pass the water through while retaining the impurities with no control over the quality of water fed to them. As a result, they rely on chemical and physical pre-treatment to inhibit fouling by organic and biological matter and scaling of supersaturated minerals. Fouling and scaling control and corrective actions drives the desalination process design and operation, increases the process footprint, and limits freshwater recovery resulting in high capital and operating costs making desalination a technology of last resort.

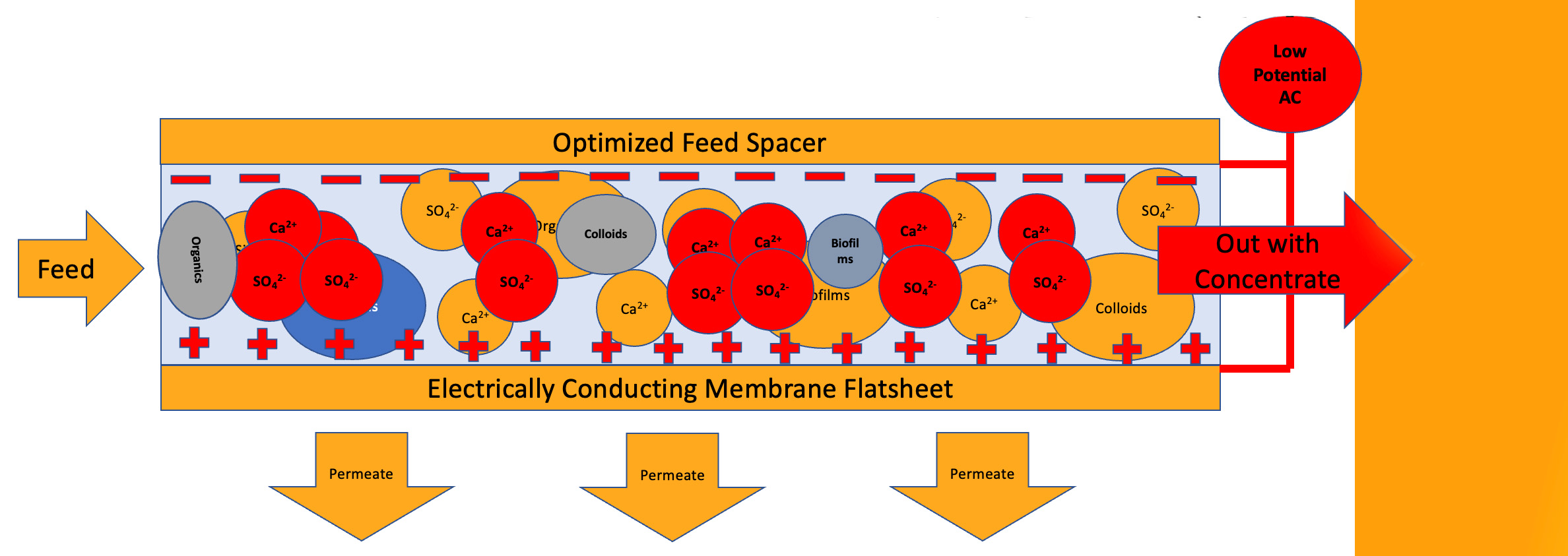

Active Membranes’ approach is new and entirely different. Our electrically conducting membranes actively inhibit scaling and fouling using a low tunable electrical potential, so that the membrane – not the process – is in the driver’s seat. With their anti-scaling, anti-fouling properties, our membranes require minimal pre-treatment, minimal usage of chemicals and consumables, operate at a higher recovery, and simplify operation, resulting in a much lower footprint, capital, and operating costs, transforming desalination into a technology of choice.

Advantages

Active Membranes’ spiral wound modules can transform any desalination membrane at any scale from a passive membrane into an active one.

Our electro-active spiral wound desalination membrane modules offer significant advantages:

Active Membranes’ benefits by the numbers

50%

40%

2x

60%

25-45%

20-25%

0

80%

Active Membranes’ benefits by the numbers

50%

40%

2x

60%

25-45%

20-25%

0

80%

Product Portfolio

| Membrane Type | 1812 | 2514 | 2521/2540 | 4040 | 8040 |

|---|---|---|---|---|---|

| High Flux BWRO | ✔ | ✔ | ✔ | ✔ | Q4 2024 |

| High Rejection BWRO | ✔ | ✔ | ✔ | ✔ | Q4 2024 |

| High Flux SWRO | ✔ | ✔ | ✔ | ✔ | Q4 2024 |

| High Rejection SWRO | ✔ | ✔ | ✔ | ✔ | Q4 2024 |